WHERE TO USE ACTIVE DRAINAGE VENTILATION?

UNNECESSARY PIPING

The concept is simple: Studor active drainage ventilation products replace traditional secondary ventilation within drainage systems and will prevent the loss of water seals in traps.

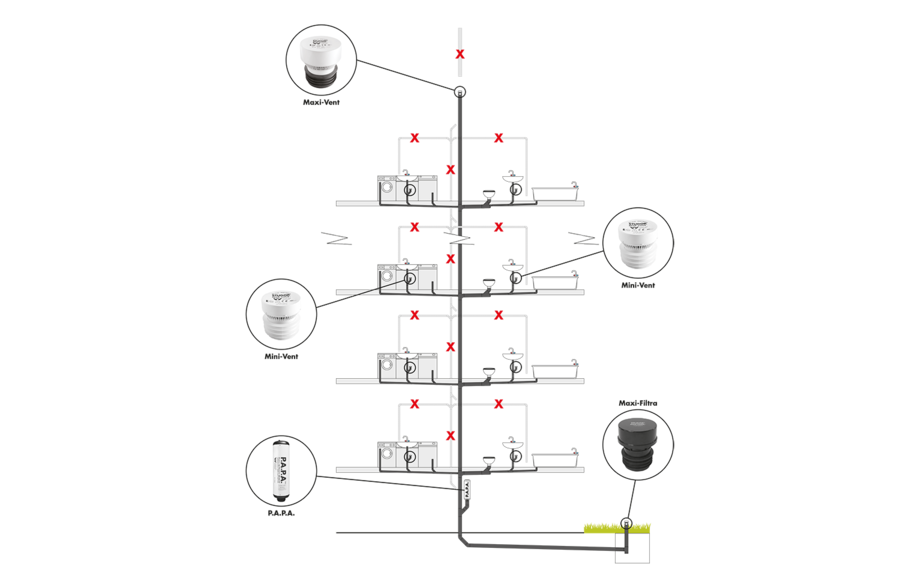

SINGLE STACK SYSTEM WITH P.A.P.A.

The single stack system with Studor P.A.P.A.s (Positive Air Pressure Attenuator) and Air Admittance Valves (AAVs) represents a complete and unique drainage and ventilation system solution for medium and high-rise buildings.

In addition to removing the need for traditional ventilation pipes, roof penetrations and back-vents, it provides a better functioning drainage system compared to traditional 2, or even 3 pipe systems. It reduces the overall material cost, installation time, installed service space, slab & roof penetrations and passive fire protection measures, allowing you to meet your project targets and sustainability goals.

- Can be installed to any pipe material and system.

- Scientifically proven and tested for total peace of mind.

- Minimal required pipe materials and roof penetrations.

- Hydraulic design support using StudorCAD.

- Can be retrofitted to troubleshoot all types of high-rise drainage issues.

- Reduces the need for fire stopping devices.

- Provides the effective protection against positive pressures in the drainage system.

- As part of a total pressure balance system, with no specialist installation requirements.

AIR ADMITTANCE VALVES

Studor Air Admittance Valves (AAVs) are negative pressure-activated, one-way vents, used in a drainage system to eliminate the need for passive pipe venting and unsightly, costly roof penetrations.

MINI-VENT

A valve for single fixture and group venting.

MAXI-VENT

A valve for stack venting, eliminating the need for a vent pipe through the roof.

TEC-VENT

A valve for where flame retardance is a priority, equally suitable for residential use.

WORLD LEADING AIR ADMITTANCE VALVES

Studor AAVs eliminate the need for passive pipe venting and costly roof penetrations with world leading performance by their unique and patented design. The negative pressure-activated, one-way vents to protect the trap seals in the drainage system by allowing the intake of air, so that the right level of pressure within the drainage system is maintained. Their unique design guarantees a lifetime performance on quick opening reaction time, zero maintenance and a 100% closing ability that meets all leading international product standards.

HOW AAVS WORK TO PREVENT BAD DRAINAGE ODOURS

Where there is a discharge of waste water within any drainage system, it will cause an AAV to open at the ‘Point of Need’ (PON). This is to release a vacuum and allow air to enter the plumbing vent pipe, thus balancing the pressure into the system so the drainage can function correctly.

WHY STUDOR AAVS ARE THE PREFERRED TECHNICAL SOLUTION

The Studor vent piping system is commonly known as an active system, rather than a conventional ‘passive’ vent pipe system, because the AAV opens when there is a need. This is described by a concept called “rapidity of reaction or instantaneous reaction”.

Thanks to Studor technology, our range of AAVs react (open) at a very small pressure differential, becoming the preferred technical solution for modern drainage systems.

Using AAVs significantly reduces the amount of materials needed in a plumbing system, increasing plumbing labour efficiency, allowing greater flexibility in the layout of plumbing architecture, and reducing long-term roof maintenance problems associated with conventional vent stack roofing penetrations.

Every Studor valve is tested twice before leaving the factory. Once installed, no maintenance is required. Each Studor product carries a 10 year warranty if used in accordance with the manufacturer's guidelines. Our track record has seen our products installed in some of the most iconic buildings all over the world.

DESIGN SUPPORT SERVICE

Aliaxis Technical Services consists of an expert team with many years of extensive experience in designing drainage systems to worldwide standards. Our expertise and understanding of these standards including EN12056-2, AS/NZS 3500.2 and ASSE 1050 / 1051 allows us to provide drainage design advice, as well as offering a service for the sign-off of drawings by a Chartered Engineer. To take advantage of our in-house drainage design support please send your drawing to studor.info@aliaxis.com.

DIGITAL SUPPORT WITH STUDORCAD AND REVIT CONTENT

The StudorCAD design tool has been developed to work with AutoCAD to further simplify the design process and provide a one-stop solution for drawing the ventilation system design. Download our StudorCAD application to make it easy to add the Studor products into your AutoCAD drawings.

The Studor Revit Content package is available to be used in Building Information Modeling (BIM). The smart content has integrated intelligence for connections to PE, PP and PVC pipe systems. Create true ‘as built' designs with the Studor Revit content package, freely available in the latest 4 Revit versions on our BIM page.

"SEEING IS BELIEVING"

See how water and air interacts in a true high-rise setting. The 'Seeing is Believing' experience is available in two unique testing facilities located in the UK and the Netherlands. They utilise clear pipe and completely visible products and fittings to demonstrate the occurrences within a real high-rise drainage system and how they are managed by the P.A.P.A. System versus a conventional vent pipe system.

|

|

|

|

|

|

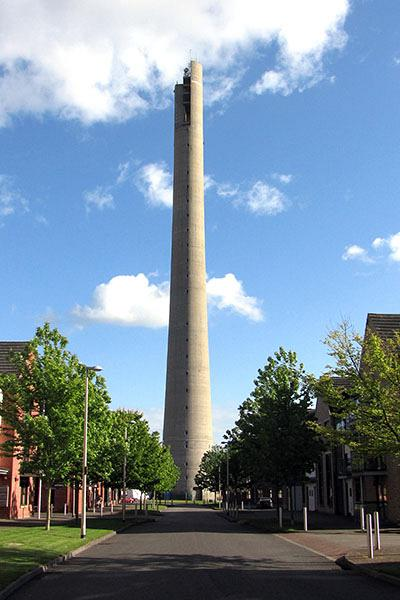

THE NATIONAL LIFT TOWER |

|

HYDRO-DYNAMICS EXPERIENCE CENTRE |

|

|

The National Lift Tower hosts the world’s tallest drainage testing installation, comprising a 96 metre soil stack fitted with the P.A.P.A. system (P.A.P.A. and AAVs) for active ventilation. Electronic pressure sensors in the test rig allow readings in the pipework to be recorded and used to objectively analyse the performance of the P.A.P.A. system versus alternative configurations. |

|

The state-of-the-art Hydro-Dynamics Experience Centre (HDEC) combines a testing facility with a customer experience centre, where customers can see precisely how water and air actually flow through our pipe systems. The HDEC is instrumental in testing new solutions and also simulates the performance of systems in specific situations for increasingly complex and/or high-rise buildings. |

HERIOT-WATT UNIVERSITY

Founded in 1821 in Edinburgh, Scotland, and has established a reputation as a leading research-led university and provider of education around the world, with campuses in several locations including Dubai and Malaysia. Heriot-Watt and Studor have collaborated for many years on research and development on a range of innovative new products. The P.A.P.A. (Positive Air Pressure Attenuator) is one of the results of this partnership; many other developments are currently in process, with the potential to revolutionise the high-rise building drainage market.

TECHNICAL GUIDANCE ON STANDARDS

In the world there are three main standards which apply to building installation products: European, Australian and USA standards. The Studor products have been approved to these standards (as well as other national standards), making them not only a technically advanced solution, but also regulatory approved products to use. Over the years the Studor technical team has contributed in raising the quality of each standard by supplying credible and scientifically proven information.

ALIAXIS HIGH-RISE BUILDING SOLUTIONS

MANAGE WATER FOR BETTER HIGH-RISE LIVING

As an expert in advanced plastic piping systems, Aliaxis has a track record of introducing new, non-conventional concepts better suited to meet the specific challenges of high-rise buildings. Aliaxis High-Rise is committed to provide architects, MEP consultants, contractors and installers with solutions to make high-rise living more feasible, comfortable, green, safe and affordable.